The Competitive Edge of China Injection Mold Makers

The manufacturing landscape has been evolving rapidly, with China injection mold makers at the forefront of this transformation. The precision, efficiency, and innovation in the Chinese manufacturing sector have made it a global hub for the production of high-quality plastic components. This article delves into the intricate world of injection molding, the strengths of China as a manufacturing powerhouse, and the exceptional services offered by companies like DeepMould.net.

What is Injection Molding?

Injection molding is a manufacturing process that involves injecting molten material into a mold to create objects of various shapes and sizes, typically made from plastic. This process is widely used due to its ability to produce high volumes of parts with tight tolerances, making it suitable for precision engineering.

Understanding the Injection Molding Process

- Material Selection: Choosing the right polymer material is crucial. Various plastics, such as ABS, polycarbonate, and nylon, are commonly used based on the required properties of the final product.

- Designing the Mold: Mold design is a critical step. It involves creating a negative image of the desired part and requires expertise to ensure that the mold operates efficiently.

- Injection Phase: In this phase, the chosen material is heated until it melts and is then injected into the mold under high pressure.

- Cooling and Solidification: Once the mold is filled, it is cooled to allow the material to solidify, taking on the shape of the mold.

- Demolding: After sufficient cooling, the mold is opened, and the finished part is removed.

The Importance of Precision in Injection Molding

Precision is paramount in injection molding. China injection mold makers emphasize achieving exact specifications to ensure that parts fit seamlessly into larger assemblies. This is particularly significant in industries such as automotive, electronics, and healthcare, where even minor discrepancies can lead to major failures.

Why Choose China as Your Injection Mold Maker?

1. Cost Efficiency

One of the primary reasons for outsourcing injection molding projects to China is the cost advantage. Labor and production costs in China are generally lower, allowing companies to benefit from substantial savings without compromising on quality.

2. Advanced Technology and Expertise

Chinese manufacturers are not just cost-effective; they also possess advanced molding technologies and skilled workforce. Investments in state-of-the-art machinery and updates to manufacturing processes have significantly improved the quality and efficiency of production.

3. Quick Turnaround Time

Working with a reputable China injection mold maker like DeepMould.net can yield shorter lead times. Efficient production schedules, coupled with experienced project management, ensure that clients receive their products promptly.

Quality Assurance and Standards

Quality assurance is a key component of the manufacturing process. China injection mold makers implement strict quality control measures at every stage of production to guarantee that the final products meet international standards. This includes:

- Material Inspection: Ensuring that raw materials meet specified criteria before they enter the production process.

- Mold Testing: Conducting thorough mold testing before full production to identify and rectify any potential issues.

- Final Product Testing: Rigorous testing of the finished parts to ensure they conform to customer specifications.

Applications of Injection Molding

Injection molding has an extensive range of applications across numerous industries. Below are some notable sectors that benefit from this manufacturing process:

1. Automotive Industry

The automotive industry relies heavily on injection molding for producing components such as dashboards, bumpers, and various interior parts, ensuring that they are lightweight yet durable.

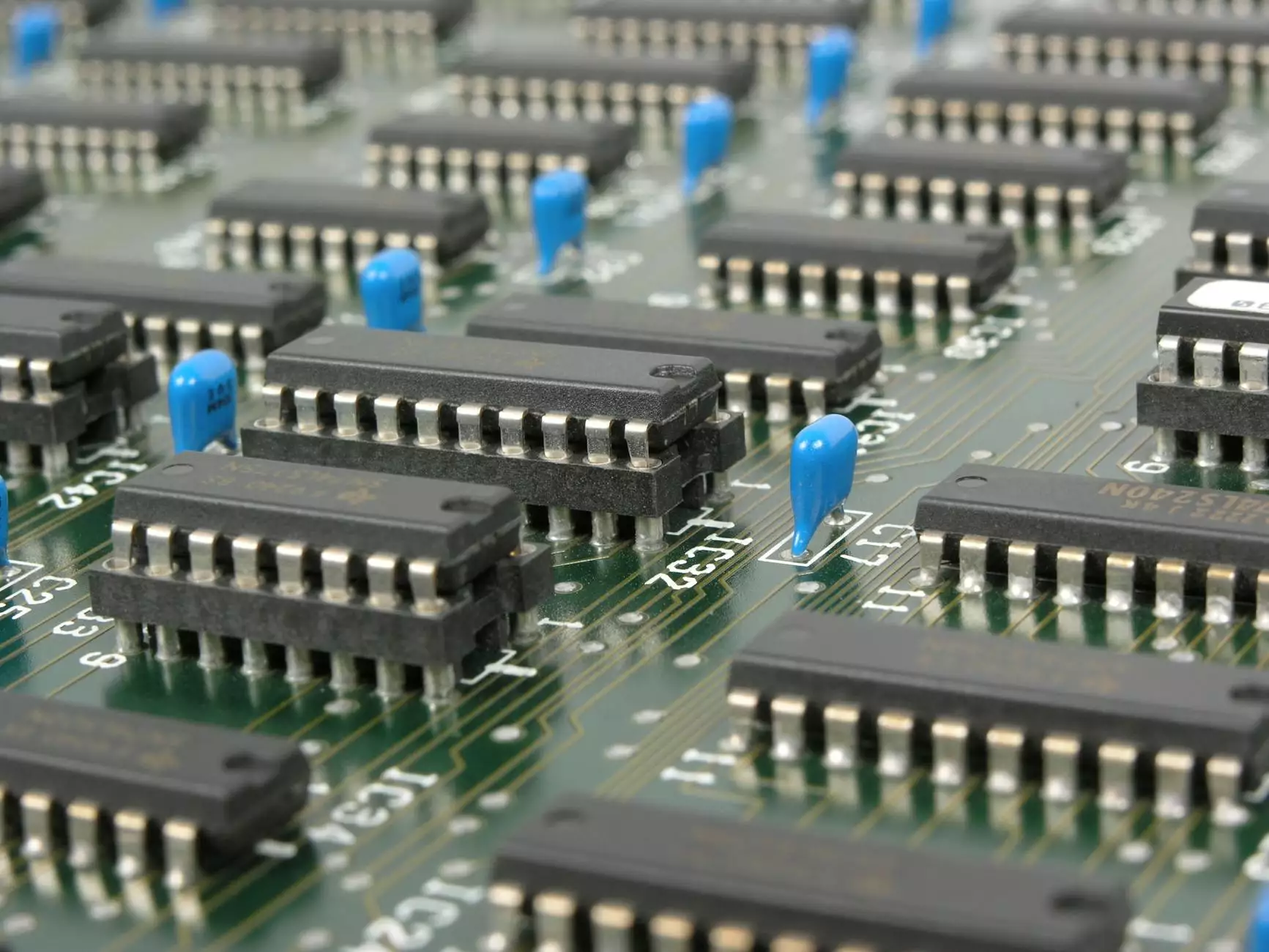

2. Consumer Electronics

Injection molding is utilized to create intricate parts in consumer electronics, including casings for phones, tablets, and computers, where precision and aesthetics are crucial.

3. Medical Devices

In the medical field, injection molding provides critical components used in devices ranging from syringes to intricate surgical instruments, under stringent quality controls.

Environmental Considerations in Injection Molding

As sustainability becomes a priority across industries, China injection mold makers are also adapting their processes. Initiatives include:

- Use of Recyclable Materials: Shifting towards using biodegradable and recyclable materials in production.

- Energy Efficiency: Implementing energy-efficient machinery to reduce the carbon footprint associated with manufacturing.

- Waste Reduction: Adopting waste reduction practices throughout the production cycle to minimize environmental impact.

Choosing the Right Injection Mold Maker in China

When selecting a China injection mold maker, several factors must be considered to ensure a successful partnership:

1. Experience and Reputation

Look for manufacturers with an established track record of successful projects, customer testimonials, and industry recognition.

2. Technical Expertise

Evaluate their technical capabilities, including the types of molding processes they specialize in and their experience with the materials relevant to your project.

3. Communication and Customer Service

Effective communication is essential for seamless project management. Choose a partner who is responsive and can provide updates throughout the manufacturing process.

Final Thoughts

The landscape of injection molding is continuously evolving, and China injection mold makers are at the helm of innovative practices that lead to high-quality production. With their expertise, advanced technology, and commitment to quality, businesses can achieve their manufacturing goals effectively. Companies like DeepMould.net exemplify the advantages of partnering with a reliable injection mold maker, ensuring that your products not only meet but exceed expectations.

By understanding the nuances of the injection molding process and leveraging the strengths of Chinese manufacturers, businesses can unlock new levels of efficiency and quality in product development. Contact a China injection mold maker today to explore how they can assist your business in achieving remarkable results.